Pourquoi choisir AMP?

Précision

Solution

Passion

Notre équipe de professionnels hautement qualifiés est animée par une passion commune pour le travail de qualité et un dévouement à offrir un service exceptionnel. Nous sommes fiers de partager notre intérêt pour le métal avec nos clients.

Découpe Laser, Pliage & Soudure

Des solutions complètes de fabrication et de traitement du métal.

Découpe Laser

Notre découpe laser rapide et précise grâce à nos 6 lasers, permet une capacité de coupe jusqu'à 288'' de long et 1'' d'épais pour répondre à vos besoins de transformation du métal en feuille.

Pliage

Nos plieuses de dernière génération offrent une capacité de pliage jusqu'à 20 pieds de longueur et 800 tonnes, pour des pièces métalliques simples ou complexes, avec une précision garantie.

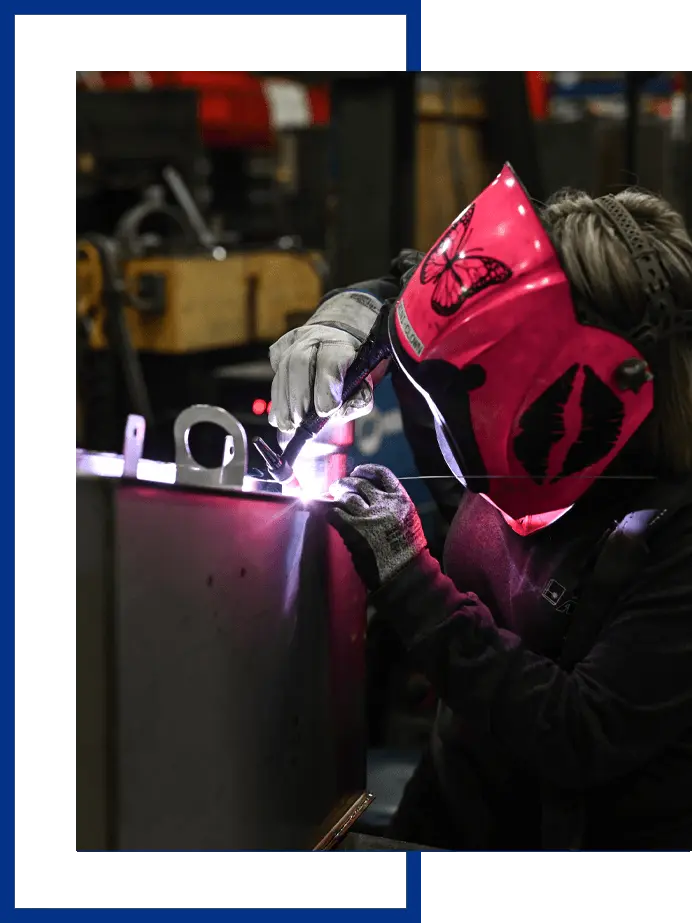

Soudage & Assemblage

Avec nos soudeurs expérimentés, nous assurons la qualité et la solidité de vos pièces métalliques en utilisant les techniques les plus avancées pour souder l'acier, l'acier inoxydable et l'aluminium.

Usinage

Notre service d'usinage CNC et manuel intégré vous permet de bénéficier d'une solution complète pour tous vos besoins de fabrication clé en main sous un même toit.

Poinçonnage

Notre service de poinçonnage à contrôle numérique est adapté aux besoins de toutes les industries, pour une production efficace et de qualité.

Autres Services

Nos services connexes de haute qualité vous permettent de bénéficier d'une expérience de production complète et sans soucis, de la conception à la livraison.

Travailler ensemble. Réussir ensemble.

Nous avons consacré 26 ans à développer notre savoir-faire pour garantir des résultats satisfaisants pour nos clients.

Qualité Garantie • Prix Compétitif Livraison à Temps

Notre objectif est de comprendre et de répondre aux besoins de nos clients en matière de qualité, de délai de livraison et de prix compétitifs. Pour ce faire, nous offrons en interne plusieurs services additionnels tels que :

- Gestion documentaire (rapports dimensionnels, PPAP, FAI, milltest)

- Gestion de fini de surface via nos partenaires sous-traitants

- Finition (ébavurage, barattage, sablage)

- Assemblage PEM

- Ébavurage

- Transport

- Rivetage

- Roulage

- Sciage

Une référence pour toutes les types d'industrie

Apprenez-en plus sur nos réussites

Ce que dit notre client

Je me sens très heureux et fier de me connecter avec cette industrie. Je suppose que c’est une industrie très productive et professionnelle. Je souhaite bonne chance et succès à cette industrie

Adam Smith

Jhon Deo

Maria Mak

Jackma Kalin

Notre force : une équipe dynamique et déterminée qui travaille ensemble pour atteindre nos objectifs communs.

Nous sommes là pour vous en apprendre plus sur le blog

Instagram Entirely visual platform unlike facebook